We, Iwata Co.,Ltd, were established in 2014.

Our interior brand "IWATA" was launched in 2017, and exhibited at Maison & Objet in Paris for the first time in the same year.

For more information about our company, please visit our corporate website.

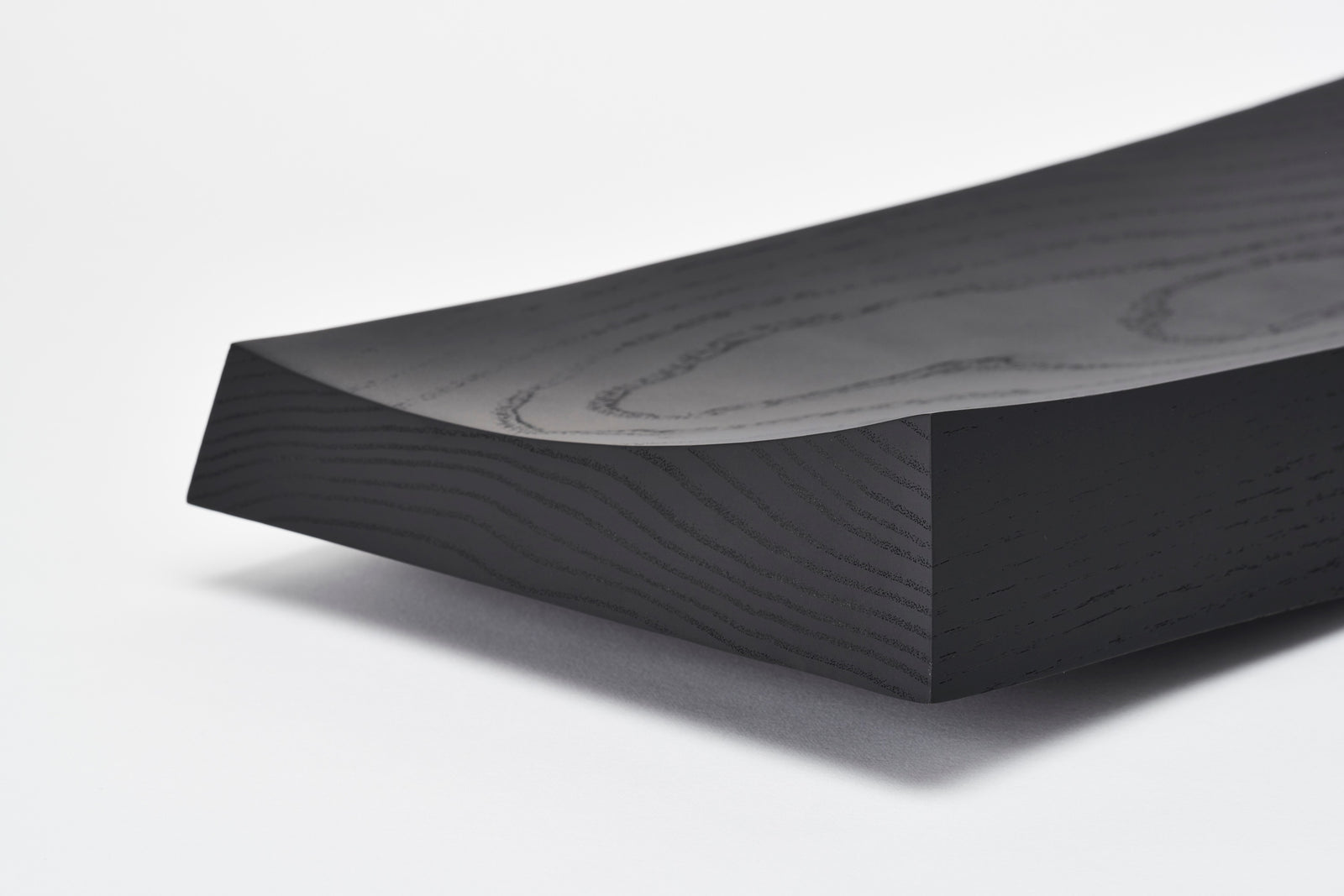

IWATA is an aesthetic woodware brand that carefully sources ideal materials and applies optimum finishes to draw out the value and enhance the true beauty of the wood so that it will stay in the heart.

We use our senses to help us when selecting our materials.

We select a material by first assuming how it will look when finished, and then using our senses to carefully inspect its: 1) place of origin and the environment in which it grew, 2) strength from the sound, 3) dryness from the scent, 4) texture by the touch, and 5) beauty from the grain’s color and flow.

We choose the finest materials and use them in the best ways possible to bring them to life in our products.

Paying close attention to the sound of blade.

Since the weight applied to the blade varies depending on the type of wood, we select the optimum: 1) hardness and angle of blade, 2) height, depth, and angle settings, and 3) spin speed of the lathe's spindle and feed speed of the blade for the material. We then shave the material while paying close attention to its sound, sight, scent and touch in order to apply the best process to the workpiece.

When it comes to the process of the finish, we apply it to each piece by hand. By doing so, we can feel the small irregularities and roughness with our fingertips and can apply elaborate polishing to give a smooth and beautiful finish that cannot be achieved with a machine.

We also make our own polishing tables for finishing which aim to stabilize the position for long hours of polishing work and to reduce the burden on our workers. We believe that improving the work environment leads to the improvement of work quality, as well as to higher productivity, resulting in a more beautiful finish.

We manage colors by adapting our own color sample criteria to minimize errors and control the color toning in 0.1g units. We also control the coating in micron units, and control the shaving with an accuracy of ±0.02㎜.

As for inspection, two lights are installed at different heights on the inspection table, and lighting with the appropriate illuminance is applied to each product, so that they can be inspected from all sorts of angles. By doing so, we can carry out precise inspections to avoid overlooking even small defects.